SERVICES

LRV CONSULTANT

“The LRV CONSULTANT can resolve many of your LRV measurement problems really fast”

Hello

- Thank you for using the METER for your LRV measurements

- Meet the LRV CONSULTANT and ask for assistance

- Our aim is to meet the needs of professionals using LRV

- Guidance on measuring materials

- Help using the APPs to check on accessibility

- For anything else about LRV, BS8493, check the Measurement of Materials (internal link)

- We worked for 30 years in research on vision impairment

FAQs

Q

I just don’t get this contrast stuff or know about LRV. What’s it all about?

A Light reflectance value (LRV) is the amount of light reflected back from a material surface – and LRV is from 0% – 100%. Dark surfaces reflect little or no light; so an all-black room or space would not be visible or navigable by us. The LRV between two surfaces that are adjacent creates CONTRAST, if there is sufficient LRV difference between them say LRV 4% and LRV 57% for example. So designers, architects and building materials’ manufacturers can make sure that there is CONTRAST between critical products and objects in buildings and environments. Many more visually impaired people could navigate the world more safely if all buildings and spaces were planned for some CONTRAST.

Q

What is CONTRAST exactly then?

A It is the difference between two measured LRV surfaces. Use the meter to measure a wall paint for example, then measure a wood architrave – check on the difference between the two LRV numbers; that gives you the CONTRAST difference. If a CONTRAST of 30+ then it is very likely that 93% of registered blind people, may see a door frame that was previously invisible to them!

Q

Why should we use a meter to measure LRV?

A A meter is the only way to determine LRV and therefore the CONTRAST between building elements. The meter excludes all ambient light so is a universal measurement for specification; all over the world in the construction and interior design industries people will trust these numbers

Q

How exact do you have to be about LRV measurements of the materials I will select for a project?

A An LRV difference between materials selected should always have a reasonable amount of leaway, but a 30 LRV difference is held by most organisations and agencies as the minimum for most building elements. A 30 contrast difference would benefit 93% of registered visually impaired people; however a difference of 35 or 40 would allow for local variations of things like air temperature – which can, surprisingly, affect the materials being measured

Q

Would 30 CONTRAST difference be enough for everything then?

A Absolutely not; for critical points like stair nosings or signage on walls a minimum of 70 CONTRAST difference is a basic requirement – the border of a sign and the sign background – for example white and navy blue – might give a 70 CONTRAST difference and be very visible. Contact the LRV CONSULTANT for more information or use the CROMOCON APP software. Available for iPhone and Android phones, it helps you check all the factors like dimension of signage text, distance away and of course lighting and Lux Levels.

Q

How important is colour then?

A Colour is in this instance irrelevant. LRV difference is the fundamental way we see the world. Colour is only additional visual information – it may prove useful for people with good colour perception – but firstly 8% of men are colour blind, and secondly an even larger number of people who are visually impaired have very poor colour vision. This why colour coding is dangerous. Yellow can appear grey, or red look brown. Measurement of colour is not critical to visibility and not a component of the actual LRV measurement.

Q

How can I find out about the light reflectance value (LRV) of materials before I choose them for a project? I may not want to purchase a meter.

A Most manufacturers of building materials now publish the LRV of their products such as marble, stone, tiles or paving. Many countries are now insisting that this data appears in product catalogues. It is not so easy to find out about the LRV of furniture, marble, wood or metal coatings. Makers, designers, architects and access consultants have to measure the LRV of their proposed materials; it is their responsibility today and shouldn’t be left to guesswork.

Q

What should we do about measuring textured or patterned materials?

A For textured materials the BS 8493 recommendation is to average 9 measurements across a sample, 15cm x 15cm approximately. The CROMOCON LRV™ METER has a setting to average these readings instantly. Small patterns can be measured similarly to provide an overall ‘optical visual appearance’ assessment of LRV for example of a surface. But this would not be appropriate for larger patterns. The LRV CONSUTANT can help with difficult materials’ measurement.

Q

How important is the size of an object or piece of furniture when considering the LRV measurement?

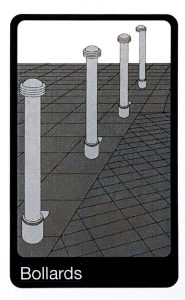

A Very important – as a scaffolding pole may only have a 50mm visible width, or a bollard a bit more, but they need to have much more CONTRAST with paving for example to be visible. That is because it is a very small area to be perceived by someone with low vision. Whereas a large sofa need not be so contrasting as it is a large size and easier to see at a 3 meter stride.

Q

What dimension of an object do we need, to assess good contrast if we are using the CROMOCON APP?

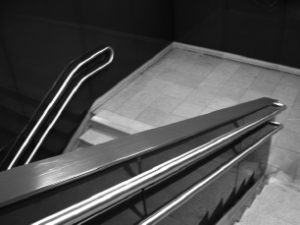

A Aways use the smallest dimension of an object if you are using the CROMOCON APP. This would be for narrow items like stair nosings, table legs, poles and bollards or handrails that are critical for safety; so always choose width not length, of a column for instance

Q

We supply very different types of flooring from tufted carpet tiles to ceramic bathroom floor tiles – how do we measure these materials?

A Certainly tufted carpet surfaces are the most difficult to measure and usually people work with the LRV CONSULTANT to achieve a measurement of the carpet appearance. Be careful of labs who will measure the extracted yarn, as this is a method used for quality control and does not represent the visual appearance of the optical mix of that surface texture in situ, from a distance – this is most relevant for accessibility for visually impaired people

Q

The LRV of our stainless steel products like handrails or kick-plates, have been asked for by contractors and architects – how can this be done with the meter ?

A Steel is very tricky to measure – the LRV can be measured sometimes on the reverse side of the material surface where there is a more matt less engineered surface appearance. On the more finished side measure the steel in two right-angled directions to accomodate the linear textures, and amalgamate or average the readings. Many people with low vision will say they find some highlights and the shadow detail of steel handrails or door handles very useful for perception.

Q

What is the most effective level of CONTRAST difference for people with low vision to perceive things?

A If CONTRAST levels of 30+ are achieved between two LRVs then many adjacent elements in an environment will be more easy to perceive. If those responsible for creating any public spaces could grasp this, and realise the enormous benefit good CONTRAST brings to so many people with low vision, then the world would be so much more accessible for independent living. Don’t forget that signage requires a much higher contrast of around 70 between text and background to be effective. Knowing where signage is, in a busy transport hub for example, and seeing the outlines of signage boards is vital.

Q

What evidence is there to check on visibility for VIPs?

A The CROMOCON APP software is based on years of research, testing and observation with hundreds of visually impaired people which is now published. The 5 Factors – identified by Dalke and her team – all need adjusting for visibility. Contrast, Lux Level, Dimension or Distance can be altered when planning critical elements in an environment or building. Using the APP helps enormously

Q

Where or what are the most important places for the use of CONTRAST?

A Firstly alerting people with low vision about extremely dangerous areas like station platform edges, openings in pavements, stair treads, columns, barriers and bollards, and pavement kerbs, are all critical for good CONTRAST for independent ambulant VIPs. Next better CONTRAST for accessibility, on all handrails, door edges, glazing manifestations and wall and doors is essential. Illustrations of these and more are available in THE CONTRAST GUIDE (internal link)

Q

A Dear Sir, thank you for your enquiry. The meter is an industry standard colorimeter that we have been supplying to the design and construction industry for over 15 years. It eliminates all ambient light so can be used anywhere any time. The hand held LRV meter is guaranteed for 12 months but we have never had one returned. We support customers in all their needs with measurement after purchase, so customers feel comfortable knowing we are here to make it easy.

Please do send us any questions you would like to submit to this page